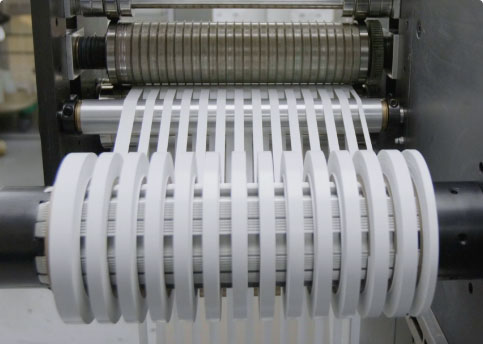

Hi-Tech has all types of slitting processes, including tight tolerance rotary rewind slitting with precise tension control, ideal for delicate material requiring extremely tight tolerances and narrow widths.

- Tight Tolerance Rotary Rewind Slitting – Extremely tight tolerances (+-.001”) can be achieved with rotary rewind tooling on certain materials. Hi-Tech has custom designed machines that can rewind narrow, delicate and pre-treated diagnostic membrane materials.

- Certified Cleanrooms – Custom tape slitting, plastic film, and film slitting services, are performed at Hi-Tech Products in certified cleanrooms.

- Shear – Shear slitting uses two rotary blades, ideally suited to cut foil, paper and denser materials.

- Score (crush cut) – Score slitting is a type of rewind slitting that utilizes circular knives to press against a steel cylinder or mandrel with material being pulled through, between the knife and the mandrel. Score slitting is more appropriate for materials of uneven thickness.

- Razor – Razor slitting is a type of rewind slitting that utilizes single razor blades. Material is pulled through the stationary blades, making clean precise cuts. Razor slitting is best suited for thin materials like films and adhesives.

- Turret Rewind Slitting – Can slit and rewind short rolls automatically. Hi-Tech custom-built turret rewind slitters are equipped with multiple rewinding stations, commonly referred to as “revolvers or turrets”, to automatically run in continuous fashion for maximum productivity & throughput. Ideal for making short rolls, slit to a specific width.

- Lathe (Displacement Slitting) – Lathe slitting is the process of taking a log of pressure sensitive material and spinning it at high speed on a stationary mandrel while a circular blade cuts the material to specified width. A fast, low cost process typically associated with cutting down rolls of tape.

- Custom tape slitting

- Plastic film slitting

- Film slitting services