Rotary Die Cutting

Rotary Die Cutting and Contract Manufacturing

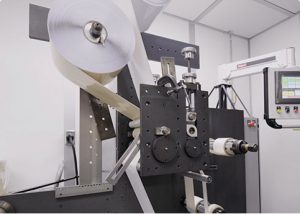

Hi-Tech Products has over 30 rotary die cutting presses, including 8 state of the art servo presses with up to 14 stations and capable of handling widths up to 24” wide. Our rotary die cutting servo presses are in certified cleanrooms and capable of island placement with electronic registration and inline heat seal pouching. Hi-Tech is capable of building one-of-a-kind presses if needed to meet your unique requirements.

Industries Served:

Every converting capability in certified cleanrooms

- Performed in-line with laminating, die-cutting and pouching

- Minimizes or eliminates scrap

- Register within tight tolerance requirements

- Optical sensors control registration

- Register to preprinted substrates

Hi-Tech can pre-print any type of pouch material and package die cut parts inline as they are cut, while printing sequential lot numbers.

- Heat Seal – creates moisture / vapor barrier

- Cold Seal – Fastest, Lowest Cost Pouching Option

- Island placement of heat seal patterns

- Foil pouching with controlled temperature, humidity and lighting

- Devices converted and pouched inline

- Foils, film, paper, Tyvek all in-stock

- Hi-Tech can package inline with both cold seal pouching and heat seal pouching materials

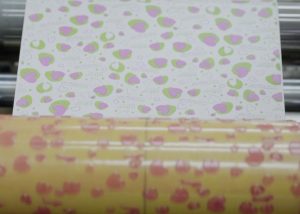

- Pre-print your release liner; either registered or random repeat

- Inline Flexo Print directly onto your die cut parts with electronic registration

- Zone coat and flood coat a wide range of specialty coatings

- Single station presses

- Multi-station presses

- Capable of laminating up to 12 layers

Pre-printed adhesive materials are accurately die cut utilizing electronic registration, leaving adhesive positioned only in the specified area(s). Adhesive free substrates can also be pre-printed and island placed.

- 8 state-of-the-art servo rotary presses capable of this process in certified cleanrooms

- Performed in-line with laminating, die-cutting and pouching

- Minimizes or eliminates scrap

- Register within tight tolerance requirements

- Optical sensors control registration

- Register to preprinted substrates

- Island placement with electronic registration

- Handling widths up to 24″ wide

- Presses in certified clean rooms

The fastest and most efficient die cutting process.

Make sure to determine the correct type of die cutting process and choose the best converting company to produce your product. Hi-Tech Products can assess your project needs and use the most cost effective die cutting process that will produce the highest quality product. Hi-Tech Product’s factories in the US and Mexico provide American engineered quality at offshore pricing. Hi-Tech Products is FDA registered, ISO 13485:2016, and ISO 9001:2015 certified. Hi-Tech is also a 3M Preferred Converter, enabling us to supply any raw material required at the most competitive pricing for any die cutting project. Whether your project calls for rotary die cutting, flatbed die cutting, or precision laser cutting, we have every capability and process available at our facilities, and all can be performed in certified clean rooms.

Hi Quality Die-Cutting / Converting

- FDA registered, ISO 13485:2016 and ISO 9001:2015 certified

- 3M Preferred Converter

- Certified clean rooms