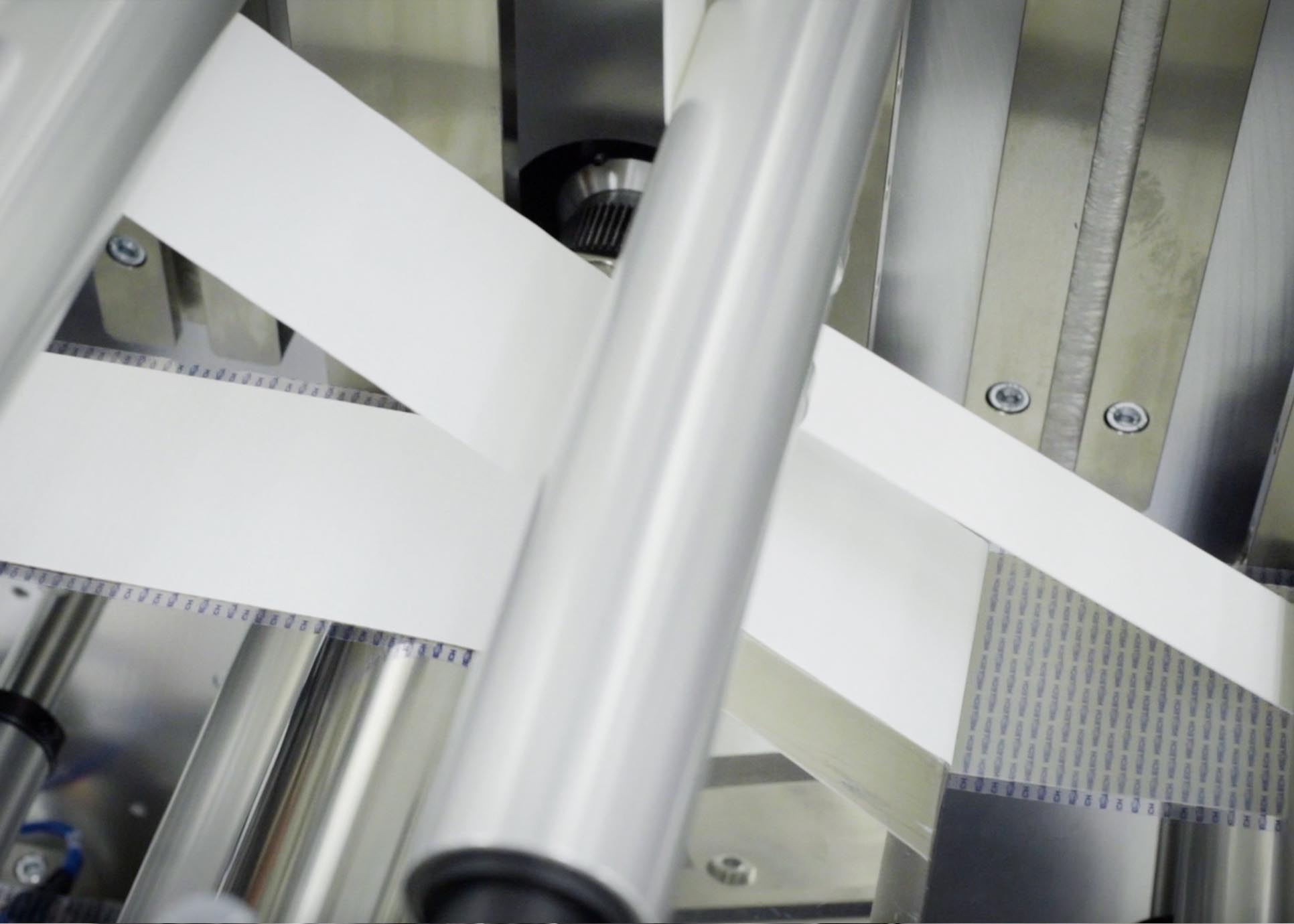

Multiple Processes to Laminate Flexible Materials into Continuous Rolls or Sheets

Hi-Tech is expert at performing several types of sophisticated lamination processes. We can laminate a variety of flexible substrates together with heat or PSA, without entrapping air or contaminants and not stretching the substrate. We have a wide range of equipment, from single station presses to sophisticated, multi-station presses, capable of laminating up to 12 layers.

- Pressure Sensitive Adhesive, Cold Lamination, or PSA Lamination – typically performed inline on rotary presses – Hi-Tech can laminate up to 12 layers inline – with electronic registration.

- Heat Lamination to PSA and Non-PSA Substrates – Hi-tech can fuse dissimilar materials together with heat – up to 62” wide.

- Patterned Heat Lamination –This process can be used to heat seal a particular area onto a continuous web or die cut component. Hi-Tech can heat seal custom patterns to any heat sealable substrate (like the heat seal of a pouch).

- Tension Controlled Lamination – PSA lamination to elastic materials. Hi-Tech has custom built presses with precise tension control, that enables Hi-Tech to laminate elastic materials together without stretching.

- Lamination of PSA to Pre-Sheeted Materials –Continuous rolls of adhesive can be laminated to pre-sheeted substrates.

- Corona Treating – Lamination with Corona surface treating in-line to bond difficult / low energy substrates. Can be used in PSA or heat lamination processes.

- Pressure & Temperature Control – Hi-Tech has sophisticated servo presses that control both temperature and pressure during the lamination process.

- Hi-Tech can convert any 3m laminating adhesive or double-sided adhesive laminate into adhesive laminating strips or adhesive laminating films to your precise specification.