Microfluidic Chip Manufacturer

Microfluidic Chip Manufacturer

- Precision Laser Cutting

- Complex Rotary Die Cutting

- Assembly and Packaging

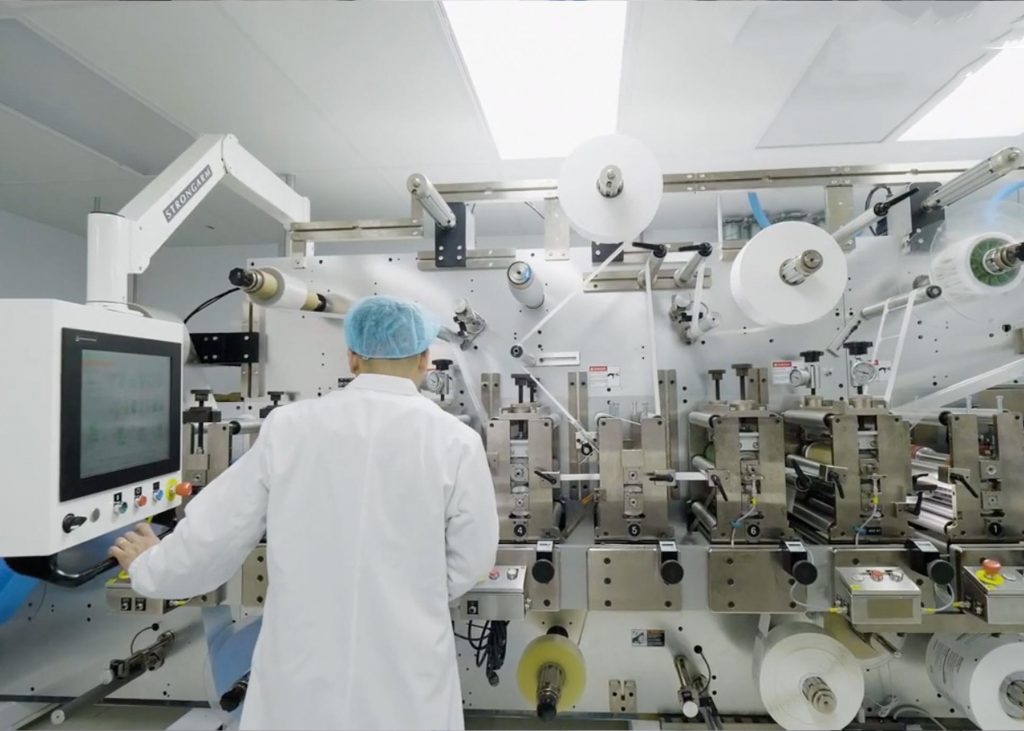

Microfluidics Converting and Assembly

Microfluidic devices are often made by constructing or stacking layers of components, with different internal geometries and properties. For example, channels created by gapping between layers may allow for blood or fluid flow. In these applications registration between layers must be accurate and precise. Converting machines often have sensors that detect registration marks or “eye marks” that affirm laminates are aligned before laminating. Lamination of multiple components also requires edge guiding and proper laminator setup.

Rotary Die Cutting

Rotary die cutting is a common method in microfluidic device converting. Hi-Tech Products offers precision rotary die cutting on state-of-the-art servo controlled presses with electronic registration. With an average of over 10 years experience, our medical die cutting specialists are trained to operate the most sophisticated equipment available and have developed unique processes unavailable anywhere else.

Precision Laser Cutting

Laser cutting is also common in microfluidic chip converting. In microfluidic device converting, lasers facilitate very intricate cuts or can be used to “drill” holes in a component. Lasers are often used in test strip converting to cut tiny conduits and vents that channel precise amounts of liquids or vapors.

Hi-Tech Products – Your Microfluidic Chip and Device Manufacturing Partner…

Hi-Tech Products offers precision laser cutting, rotary die cutting, converting, as well as assembly and packaging in certified clean rooms. Our Factories in the US and Mexico provide American engineered quality at offshore pricing. Hi-Tech Products is FDA registered, ISO 13485:2016, and ISO 9001:2015 certified.

Hi-Tech Products – Precision Die Cutting Since 1979

Our Factories in the US and Mexico provide American engineered quality at offshore pricing. Hi-Tech Products is FDA registered, ISO 13485:2016, and ISO 9001:2015 certified. Over 200 highly skilled employees perform every type of converting process on any flexible substrate.

Hi-Tech’s experienced Engineering staff will help you select the optimum manufacturing process to meet your die cutting and converting projects unique requirements.