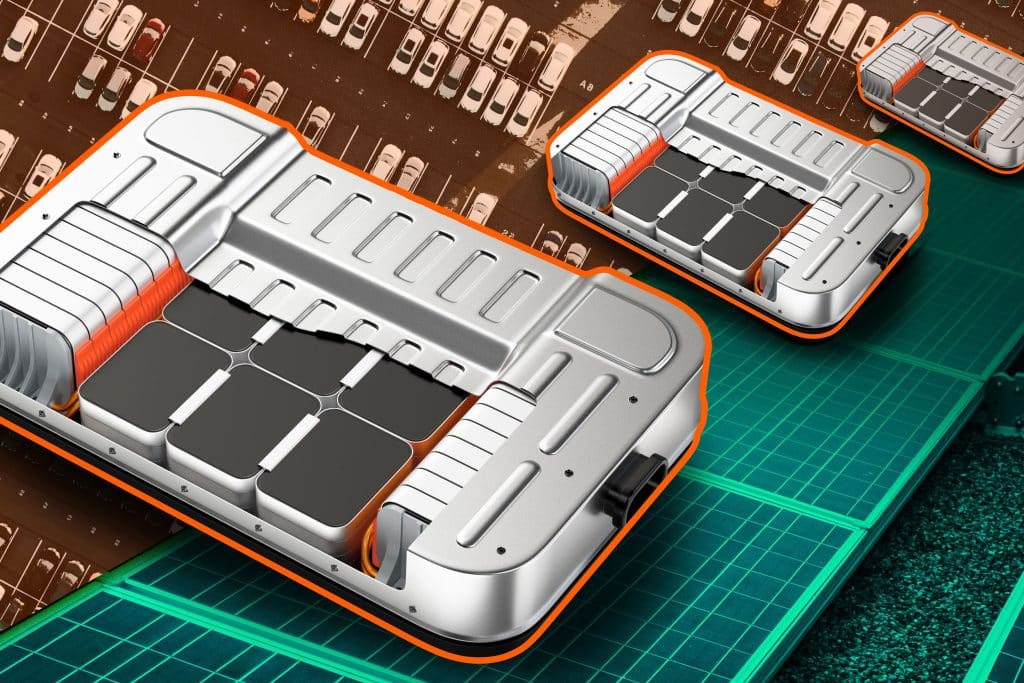

Energy Storage Components

Battery Component Manufacturing

Hi-Tech Products offers a wide range of capabilities and expertise in materials selection for EV Battery components manufacturing.

Compression pads protect EV battery cells from vibration and impact. Battery manufacturers surround, pouch and prismatic battery cells, with foam compression pads by placing them between each cell using pressure-sensitive tapes.

Single and double-sided pressure-sensitive adhesive tapes can ensure the structural integrity of EV battery packs. Bond battery cells together, for safe and reliable battery operation, with a variety of tape designs, including dielectric and flame-retardant designs.

Thermal interface materials (TIMs) are bonded to heat sink or chiller plate materials to facilitate heat transfer and promote EV battery temperature regulation. Flame retardant adhesives as well as silicone or acrylic based pressure sensitive adhesives offer excellent adhesion to TIMs.

To protect against thermal runaway, flame-retardant adhesives and single or double-coated filmic tapes bond materials such as ceramic fiber and mica to UV battery cells.

Tight seals within gasket assemblies are crucial for safe and reliable EV batteries. Foam tapes, both pressure-sensitive and heat-activated, can create a dependable seal that bonds closely to EV battery components preventing the intrusion of water, fluids, and particulates.

EV battery cells must be insulated to protect components from stray electrical current and electromagnetic interference. Dielectric films, single sided tapes, or double sided tapes can be applied directly to components or used to attach foam compression pads and other materials for added insulation.

Double coated and flame retardant adhesives protect busbars by providing electrical insulation and flame resistance for flexible printed circuits

Polyester or polyethylene terephthalate (also known as PET film) is particularly valued for its ability to meet critical industry standards for flammability and dielectric properties. Encapsulating cell to cell foam or insulation reduces the effects of vibration, shock, moisture, corrosion, and chemical solvents. Encapsulation also helps with thermal runaway, heat transfer, flame reduction, and electrical insulation.

EV battery cells can be wrapped in single or double coated tapes that incorporate dielectric films to guard sensitive components from harmful electrical currents.

Component Manufacturing Applications

Hi-Tech Products offers a wide range of die cutting capabilities and expertise in materials selection for energy storage manufacturing applications.

Batteries

- EMI/RFI Shielding

- Electrical Insulation

- Bonding and Joining

- Gaskets and Sealing

- Vibration Dampening

- Surface Protection

Manufacturing Capabilities

Adhesive film converting, die cutting, and rotary die cutting is performed in our +100,000 sq ft facilities. Over 200 highly skilled employees perform every type of converting process on any flexible substrate. Our manufacturing facilities are located in both the USA and Mexico.

Hi-Tech’s experienced Engineering staff will help you select the optimum manufacturing process to meet your die cutting and converting projects unique requirements.

Rotary Die Cutting

Flat Bed Die Cutting

Precision Laser Cutting

RF Welding

Ultrasonic Welding

Laminating

Slitting and Rewinding

Clean Room Converting and Manufacturing