Hi-Tech Products Die Cutting and Converting

Die Cutting Services

Die Cutting Services and Every Converting Process under one roof.

Adhesive film converting, die cutting, and rotary die cutting is performed in our +100,000 sq ft facilities. Over 200 highly skilled employees perform every type of converting process on any flexible substrate. Factories in both the USA and Mexico.

Hi-Tech’s experienced Engineering staff will help you select the optimum manufacturing process to meet your die cutting and converting projects unique requirements.

Click on these die cutting services for more details:

- Rotary Die Cutting Services

- Die Cut Parts for Automation Assembly

- Kiss Cutting

- Multi-Layer Laminating

- Island Placement with Electronic Registration

- Inline Heat Seal Pouching & Cold Seal Pouching

- In-line Lot, Barcode, & UDI Printing

- Slitting / Tight Tolerance Rotary Rewind Slitting

- Low-cost Packaging & Assembly in Mexico

- Flexographic Printing

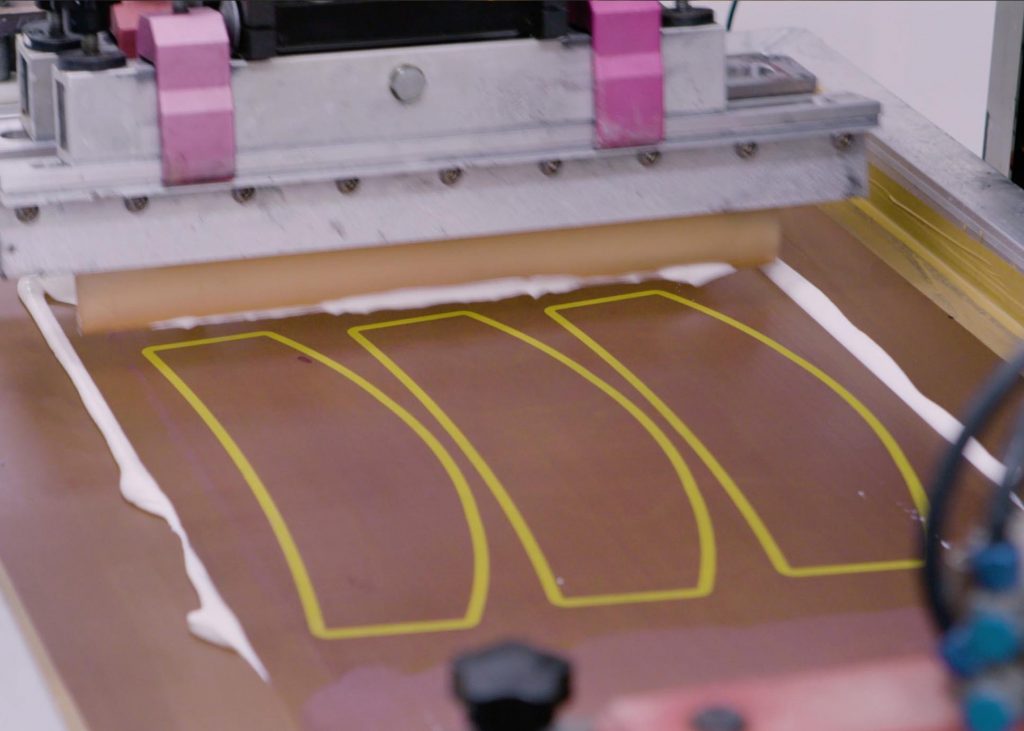

- Silkscreen & Pad Printing

- Corona Treatment

- RF Welding / Medical RF Welding in Certified Cleanroom

- Multilevel Scoring & Perforating

- Cleanroom Die Cutting & Cleanroom Converting Services

- Precision Laser Cutting

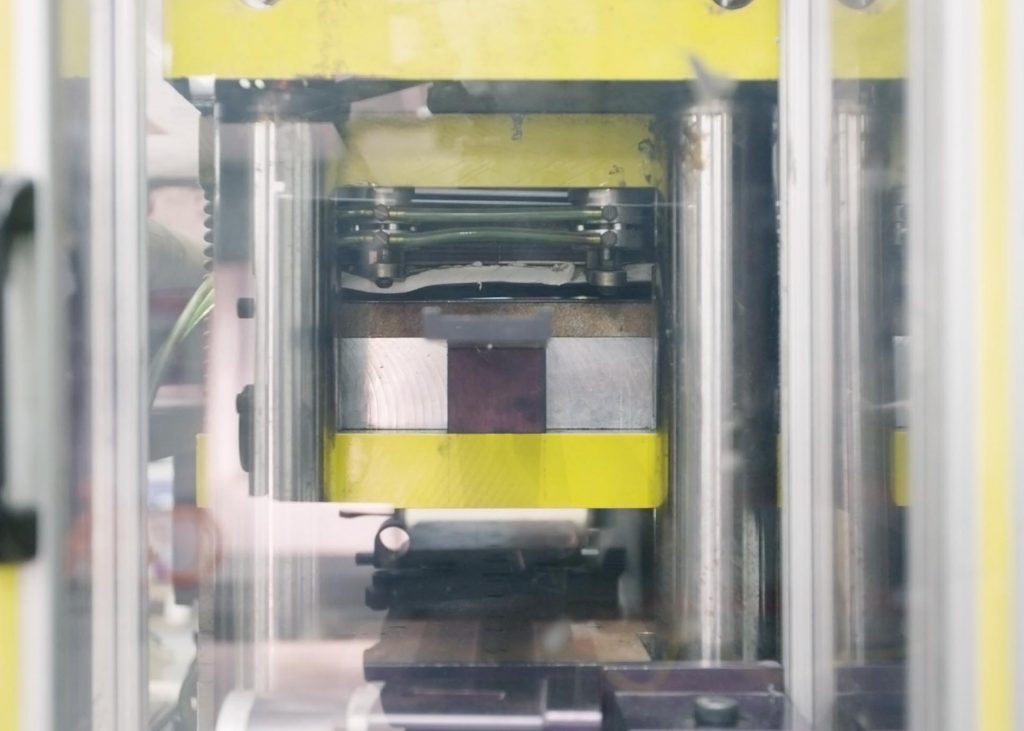

- Class A (Matched Metal) Die Cutting

- R&D Prototyping

- Flatbed Die Cutting

- Laminating / Sheeting Services

Clean Room Converting Capabilities

Hi-Tech Products has the rotary die cutting capabilities to meet your converting project requirements.

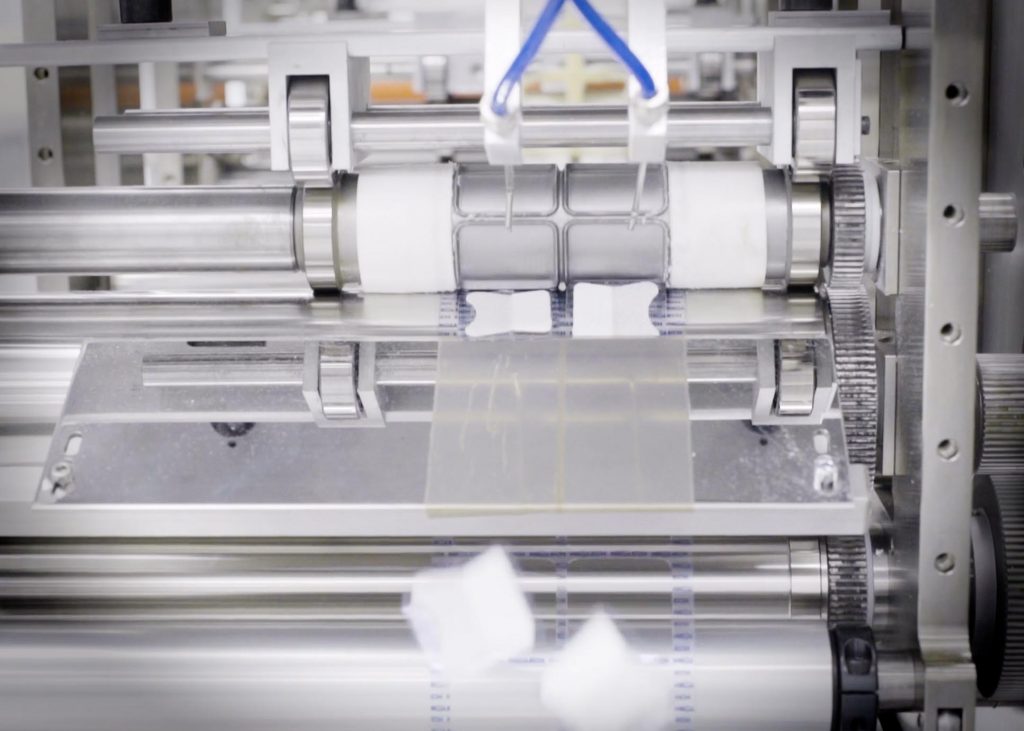

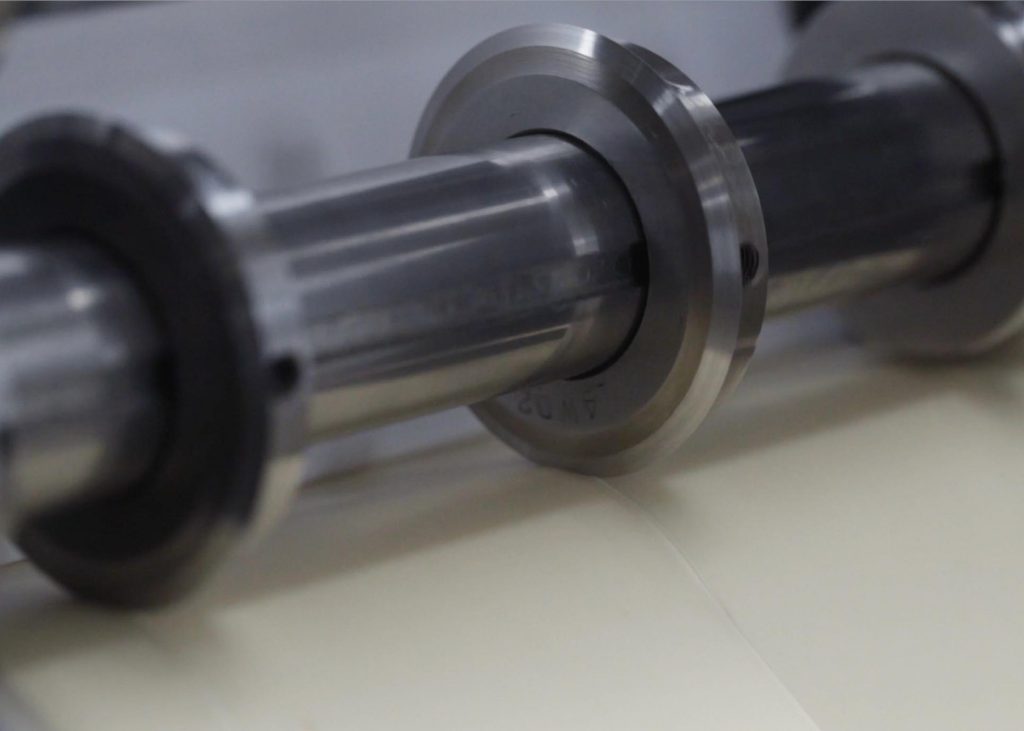

Equipped with over 30 rotary presses in the US and Mexico, Hi Tech Products is the leading rotary die cutting and flatbed die cutting company. Hi Tech’s state of the art servo driven presses are capable of electronic registration and in-line heat seal pouching, which produce parts to extremely tight tolerances and minimize or eliminate scrap. Hi Tech’s presses have the capacity to do flexographic and inkjet inline printing, as well as sequential numbering. Electronic registration enables registration to pre-printed substrates. Hi-Tech Products can custom build one-of-kind rotary die cutting presses for demanding applications unachievable with conventional presses.

Labor intense flatbed die cutting is performed at our Tijuana, Mexico facility. We have several types of flatbed die cutting presses capable of cutting materials several inches thick and production of parts up to 10 ft x 10ft. Both our Tijuana, Mexico and Buena Park, California facilities are FDA registered, ISO 13485:2016 and ISO 9001:2015 certified. Medical device assembly and packaging is done in our Tijuana Mexico facility with American engineered quality–offering the benefit of offshore pricing in class 100,000 clean rooms.

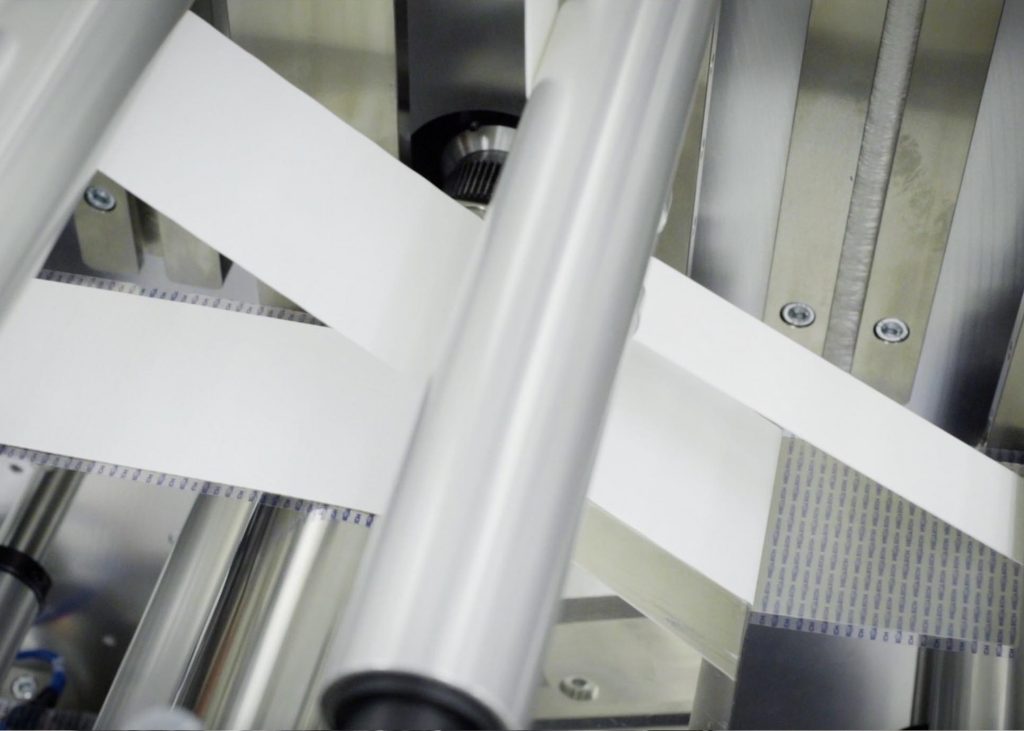

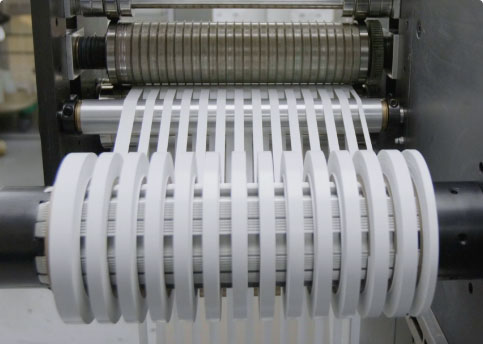

Hi-Tech Products can multi layer laminate up to thirteen substrates utilizing pressure sensitive and heat laminating equipment. We have extensive slitting, sheeting, and rewinding capabilities. Tight tolerance slitting includes shear, score, razor, lathe and rewind. We can also achieve the precision tension control necessary for converting delicate and stretchy materials. Other capabilities include corona treating material allowing for better adhesion and print quality, Class A die cutting, and laser cutting performed in a controlled environment.

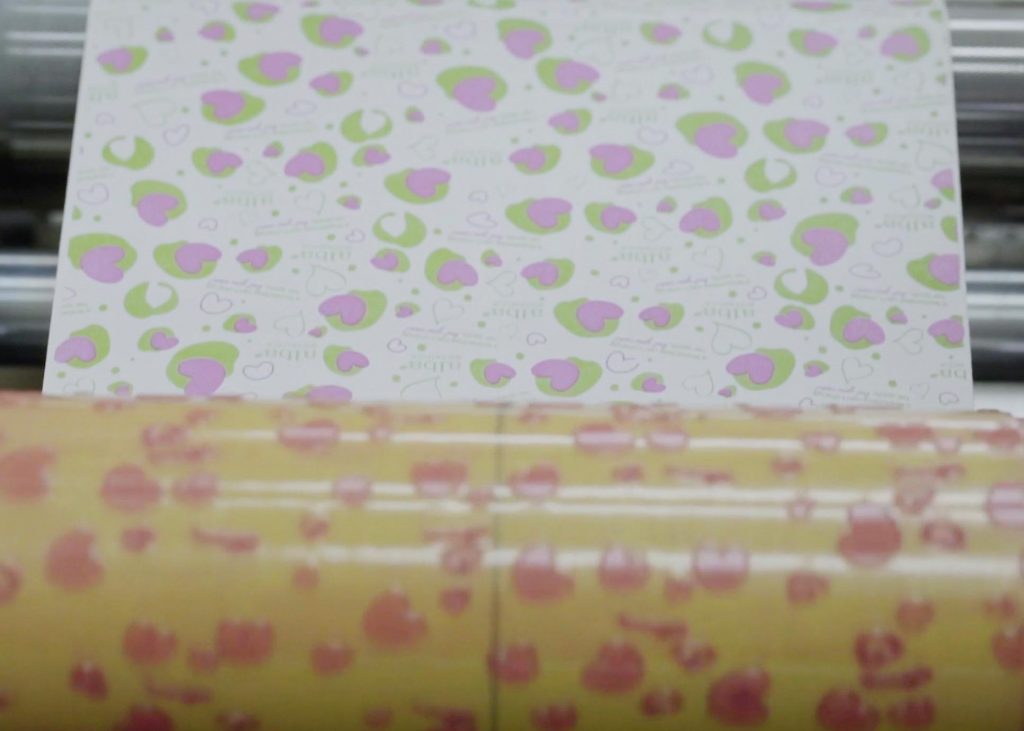

Printing capabilities include flexographic, silkscreen and pad printing.

Contact us today – Hi-Tech Products has all the die cutting services as well as converting and assembly capabilities to ensure a precision product every time.